Milling machines: Process metal efficiently and precisely

The heart of every milling machine is the principle of machining: the cutting machine tools remove material using rotating cutting tools. This creates surfaces, grooves, or pockets, even up to precise holes. Combining their three feed axes with the correct tools and/or accessories results in complex spatial contours such as gear housings.

In addition, milling machines are a symbol of innovation and efficiency in manufacturing technology. They can be found in both smaller workshops and large industrial companies, and play a key role in increasing the scalable manufacturing capacity and innovation of companies. Their adaptability and versatility in precision work makes them an indispensable component in the modern industrial landscape

Milling Machines: Metalworking Made Easy

Here are some of the main applications of milling machines:

- Shaping and contour machining: Milling machines are ideal for producing complex shapes and contours. The precise control of the cutting tools allows both simple and complex geometries, such as grooves, pockets, holes and profiles, to be manufactured.

- Surface finishing: In addition to shaping, surface finishing plays an important role. Milling machines can be used to smooth surfaces, polish them, or create special surface structures.

- Manufacturing precision parts: Industries such as automotive, aerospace, mechanical engineering, and medical devices require high-precision components. Milling machines provide the accuracy and repeatability required to produce these parts.

- Prototyping and one-off production: Milling machines are also very important in prototype development and one-off production. They allow engineers and designers to create prototypes and make adjustments quickly and efficiently.

- Tool and mold making: Milling machines are used to produce precise molds and tools for the mass production of plastic parts, metal parts and other materials. As you might imagine, this is relevant to nearly every manufacturing industry.

- Repair and maintenance: Milling machines are also indispensable in the maintenance and repair of machines and equipment. They make it possible to rework damaged parts, or to produce new replacement parts that fit perfectly.

- Series production: In the series production of metal parts, CNC (Computerized Numerical Control) milling machines offer high productivity and efficiency due to their automation and programmability. This automation allows for the consistent, high quality production of large quantities.

Different Types of Industrial Milling Machines

Milling machines offer a wide range of possibilities for metalworking - from high-precision and automated processes, to flexible and manual applications. Each machine has its specific advantages and areas of application that make it suitable for different industrial requirements. Here are some of the main types of industrial milling machines:

What are vertical machining centers?

Vertical machining centers are state-of-the-art machines that have been specially developed for the precise and efficient machining of complex workpieces. In these machines, the milling head is arranged vertically, making them particularly suitable for machining flat workpieces and for producing complex contours.

Vertical machining centers are often equipped with CNC (Computerized Numerical Control) controls that enable automatic control and programming of the machining processes. This leads to high repeatability and productivity, making them ideal for making high-precision components at scale in the automotive, aerospace, and medical technology industries.

Whether universally applicable vertical versions, or state-of-the-art 5-axis machining centers, every machine in the KNUTH USA product portfolio is equipped with automatic tool changers and state-of-the-art CNC control technology that enables easy programming and operation.

CNC drilling machines: Ideal for large workpieces

A CNC-controlled milling-drilling machine is specially designed for precise drilling, milling and turning of large and heavy workpieces. It has a horizontal spindle that moves along the X-axis, while the work table positions the workpiece along the Y and Z axes. This allows countersinking, turning, drilling and milling work to be carried out on four sides in just one setup.

Thanks to the CNC control, complex drilling patterns and machining operations can be programmed and carried out automatically. CNC drilling machines are ideal for machining large components such as machine beds, machine frames, engine blocks or turbine housings. The tool changer for CNC drilling machines is an automatic system for changing different tools quickly and efficiently during the machining process, thus allowing for a variety of different machining tasks. Machine downtime and setup times are reduced due to this automation.

The modern CNC-controlled milling-drilling machines from KNUTH are easy to program and enable the machining of complex contours and hole patterns. Swiveling tables with long travel distances facilitate handling and can optionally be replaced by an electric motor-controlled, positionable rotary table.

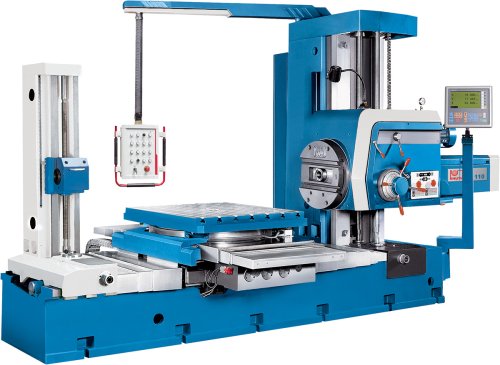

Conventional boring machines: Perfect for simple drilling and milling tasks

Conventional boring machines are traditional machines that are manually operated and are known for their simplicity and robustness. These machines have a horizontal spindle and a movable work table - similar to CNC boring machines, but without the automated control. This allows for drilling, countersinking, turning and conventional milling on four sides in just one setup:

Conventional boring machines are ideal for simple drilling and milling tasks as well as for repair and maintenance work. They are often used in smaller workshops and repair shops where flexibility and ease of operation are valued

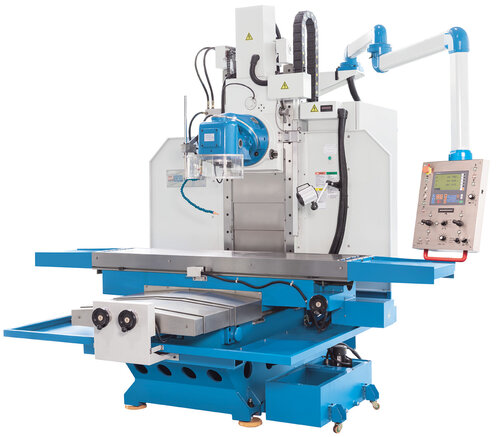

Conventional vertical milling machines: Flexible and user-friendly

Ideal for repairs, training and small batches: Conventional milling machines are equipped with a horizontal and a vertical milling spindle and at least three feed directions. This produces precise holes, complex housings and gears.Tool milling machines offer versatile machining options through vertical and longitudinal movements over a console, which can be supplemented with various tables or dividing devices. A dividing device is a clamping device for the precise positioning and further rotation of workpieces. This enables evenly distributed, angle-accurate machining steps to be carried out on the workpiece.

Conventional vertical milling machines are versatile and widely used tools in metalworking. They are manually operated, making them ideal for smaller workshops and one-off production. These machines offer great flexibility and are easy to operate, which is why they are a preferred choice for many craft businesses and smaller production facilities.

Buy milling machines from KNUTH USA

Are you looking for reliable and high-performance solutions for metalworking? KNUTH USA is a leading provider of metal milling machines that impress with innovation, quality and comprehensive service. With a wide range of machines, KNUTH USA covers the diverse requirements of metalworking. Many machines are also available on short notice. You can request a non-binding quote on the respective product pages in our shop. The KNUTH team will be happy to advise you in detail to find the perfect milling machine for your company. Just give us a call or write us a message.

Comprehensive service: installation, training, repair

We provide comprehensive support during the installation and commissioning of your new milling machine and offer training for you and your employees on how to use it. Our technical support and repair service is available for all machine categories from the KNUTH portfolio. Our service staff are your central contact for technical questions, and we also work with a network of experienced local service partners. In addition to classic maintenance, we also offer modern remote maintenance services for CNC machines via a remote maintenance application. Thanks to our extensive spare parts warehouse, we can provide most components quickly - even for older machines. This ensures that your machines have a long service life.

What sets KNUTH apart

Proven History

Founded in 1923, KNUTH has over a century of experience supplying machine tools to metalworking professionals worldwide.

Global Support Network

We maintain service centers and inventory in multiple regions, enabling fast delivery, parts availability, and expert support wherever your shop is located.

Reliable Machinery

KNUTH machines are built for daily use in demanding environments. We focus on long-term reliability, ease of maintenance, and consistent performance.

Explore More Machine Tools

KNUTH supplies a full lineup of turning machines, grinders, and drilling equipment. Explore our catalog to find the tools that match your shop’s needs.