SERVO MILLING MACHINE

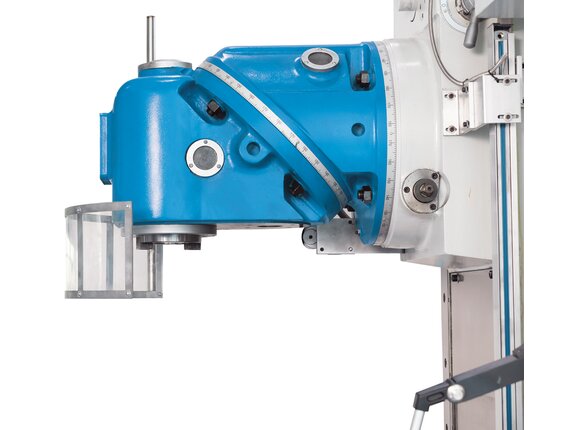

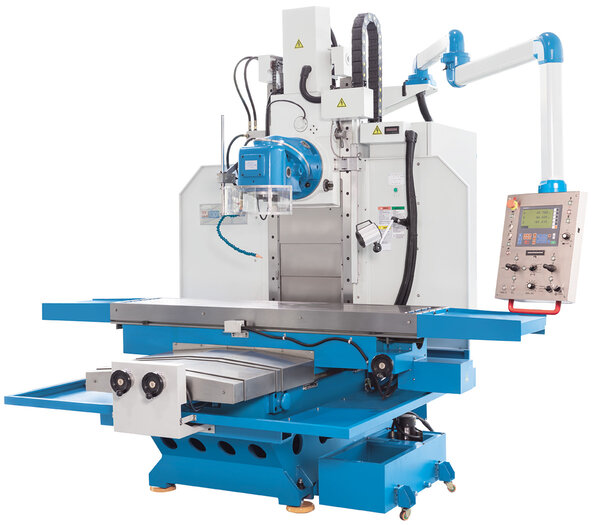

Servomill® KB 1500The versatile Servomill® KB 1500 bed-type milling machine with servo-conventional feed technology combines a heavy-duty machine frame, wide guideways and high drive power for superior cutting performance. The universal milling head can be swivelled in two planes and positioned at almost any angle. Long milling arbors can also be used for horizontal machining. With electronic stops, electronic handwheels and additional milling functions, the Servomill® brings the benefits of CNC technology to large-scale production without the need for programming. The large work area and high maximum table load allow machining of large, complex workpieces. Together with the extensive range of accessories, this model is the ideal solution for plant and machine construction.

- Servo feed technology with electronic handwheels

- Ball screws in all axes

- 3 x 3 electronic stops

- Universal milling head with 2 swivel axes

- High maximum workpiece weight

- Infinitely variable spindle speed