HOT DEAL

This machine is part of our seasonal sale.

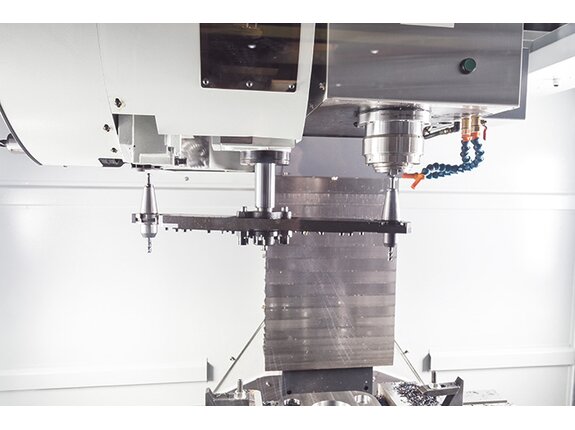

C-FRAME VERTICAL CNC CENTER

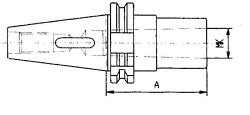

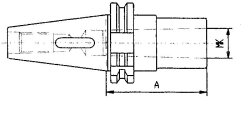

Vector 1000 M Si (15" Multitouch-Panel/BT40)The Vector series is the compact all-in-one machining solution, designed and pre-configured for complex manufacturing challenges. This variant from the series corresponds to the standard machine in all data and dimensions, but is configured with different equipment. Further information can be found in details and standard equipment.

- Extra-wide Y-shaped Meehanite column for maximum stability

- Designed for multi-shift operation

- With 15" multi-touch panel – more intuitive, faster and more convenient