The business is known for robust products with carefully thought out details. Bernd Schneider learned about the tools of the trade in his father’s metalworking operation, and he started building grills in his free time. In 1997, he turned his hobby into a business that now has 20 employees.

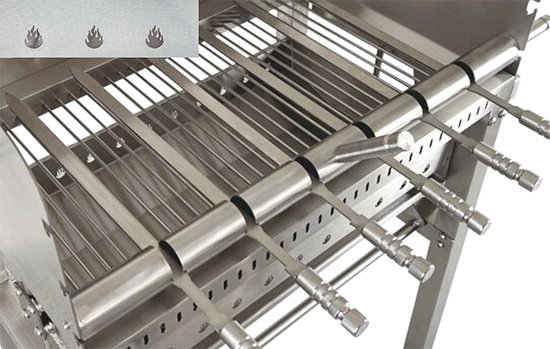

Schneider processes about 100 tons stainless steel sheets, tubes and round bars per year to produce the locally popular swivel grills and also classic wood-fired grills plus various grill accessories. “Grills for gastronomy customers and end users are our major business. But we also manufacture rack and frame technology products for the furniture industry, mostly in small batch or single part productions,” says Bernd Schneider.

Since 2017, he has been using a KNUTH Laser-Jet 2512 with a Fiber-Laser 2000 for their production. He saw the machine at the Euroblech Trade Show in Hannover, Germany, and after consultation with the KNUTH team, the excellent price-performance ratio convinced him. The fully functional entry-level model takes up less space while still providing travel distances up to 2500 mm. Focus tracking and capacitive height scanning ensure high cutting quality, and automatic cutting process guidance ensures optimum plunge-cuts as well as corner and radius cuts.

The system includes user-oriented operating software and an integrated technology database, which ensures that operators quickly can start production after a brief on-site training. Another plus: Since workpiece sheets are also vacuumed on top, cutting emissions are kept a minimum.