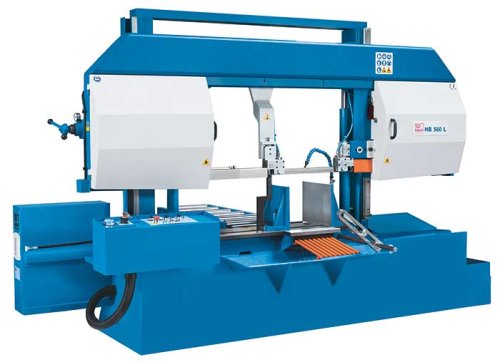

Horizontal Mitre Cutting Bandsaws

A workhorse in just about every shop and production facility across the globe, mitering bandsaws are suitable for many applications ranging from aluminum to tool steel. We offer manual, semi-automatic, and fully automatic mitering bandsaws with capacities as great as 1.000 mm and available NC or CNC control. Our portfolio includes models with angle cuts up to 60° and dual miter. Available in scissor-style and double column design, KNUTH mitering bandsaws are known for quality, reliability, and longevity.

A workhorse in just about every shop and production facility across the globe, mitering bandsaws are suitable for many applications ranging from aluminum to tool steel. We offer manual, semi-automatic...

read more