ENGINE LATHE

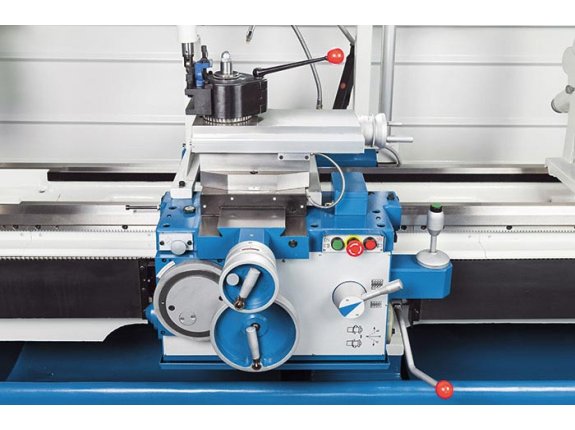

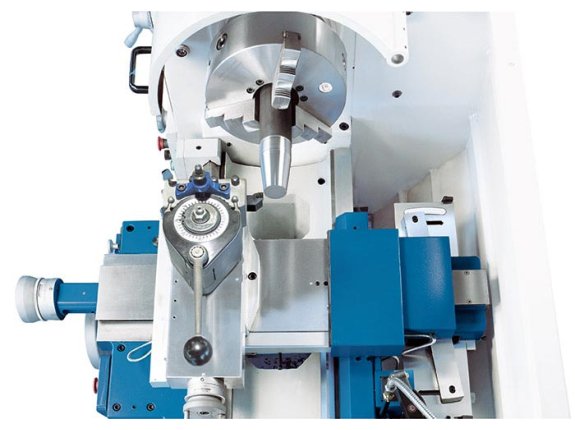

Sinus 400/3000 DSinus D is the largest series in the universal lathes segment. The construction follows a classic design but is based on a heavy, one-piece cast machine bed. As with heavy-duty lathes, the frictional connection between the motor and the spindle takes place via a manual multi-disc clutch. With integrated functions such as the removable bed bridge, rapid traverse and a taper turning device, this series offers optional solutions for machining long workpieces or large flanges.

- One-piece heavy-duty cast bed for increased rigidity

- Sturdy headstock design with large spindle bearings

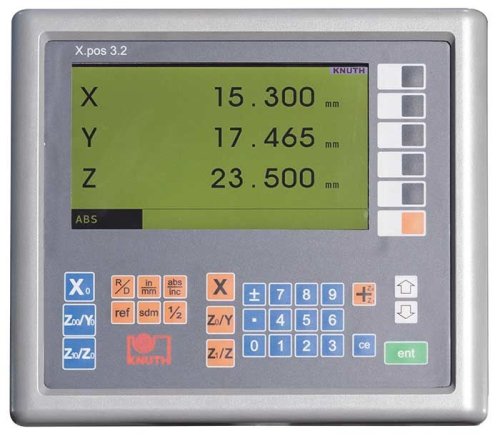

- Rapid feed on 2 axes for fast positioning

- Taper turning attachment for additional applications

- Well-designed safety functions