Need help finding a machine?

We will gladly assist you in making the right decision to achieve your business goals

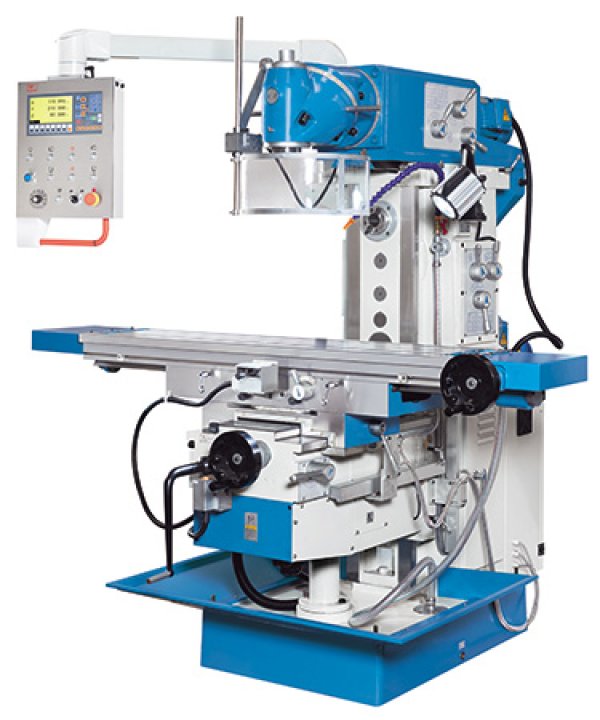

The versatile universal milling machine complements the tried and tested UWF 3. Both models have the large work area, the universal milling head and the horizontal spindle in common. The new UWF 3.2. however has a slightly higher speed range and an infinitely variable servomotor feed, which extends its range of application. Together with the extensive equipment, this model is also ideally suited for repair workshops as well as training and production departments.

| Working area | |

|---|---|

| Table set up area | 1370 mm x 320 mm |

| Table load capacity (max.) | 260 kg |

| Table swivel range r/l | 45 deg |

| Number of T-slots | 3 positions |

| T-slot (width x spacing) | 14 mm x 80 mm |

| Travels | |

|---|---|

| Travel X-axis | 1000 mm |

| Travel Y-axis | 360 mm |

| Travel Z-axis | 400 mm |

| Vertical milling head | |

|---|---|

| Spindle speed (vertical) | 45 1/min - 1660 1/min |

| Spindle mount | SK 40 DIN 2080 |

| Throat | 300 mm - 765 mm |

| Vertical spindle-to-table surface distance | 260 mm - 660 mm |

| Milling head swivel range | 360 deg |

| Rapid feed | |

|---|---|

| Rapid feed X-/ Y-axis | 1335 mm/min |

| Rapid feed Z-axis | 1000 mm/min |

| Horizontal Milling Spindle | |

|---|---|

| Spindle speed (horizontal) | 35 1/min - 1500 1/min |

| Spindle mount | SK 40 DIN 2080 |

| Horizontal spindle-to-table surface distance | 75 mm - 475 mm |

| Feed | |

|---|---|

| Feed speed X-axis | 30 mm/min - 830 mm/min |

| Feed speed Y-axis | 30 mm/min - 830 mm/min |

| Feed speed Z-axis | 23 mm/min - 625 mm/min |

| Drive capacity | |

|---|---|

| Motor rating horiz./ vert. | 3 kW |

| Measures and weights | |

|---|---|

| Overall dimensions (length x width x height) | 1,9 m x 1,75 m x 2 m |

| Weight | 1950 kg |

Explore the range of compatible accessories in stock

We will gladly assist you in making the right decision to achieve your business goals

All machines need an occasional pit stop. With our all-encompassing plans for service, training and installation you always will get the best possible performance from your KNUTH machines.

View Services

Get a first-hand impression at one of our facilities! Many machines in our portfolio are always in stock and available for demonstration.

Book a Demo

We have received your request and appreciate your interest! Our sales representative will get in touch within 1 business day.

Please refresh the page and try submitting the form again.

We have received your request and appreciate your interest! Our sales representative will get in touch within 1 business day.

Please refresh the page and try submitting the form again.